Brief

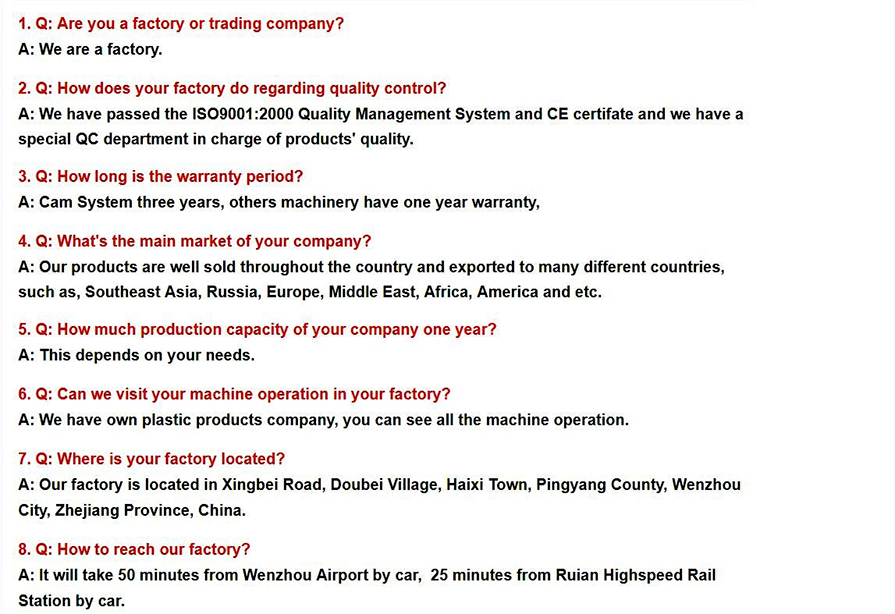

- The main parts , such as screw barrel , screen exchanger ,T-die adoptsuperior alloy steel(38CrMoAIA) with high hardness,strong corrosions resistance and long operation life after nitrogen treatment.

- The screw adopts Big L/D Ratioto ensure the product has good plasticizing , stable extrusion

- The Non-stop fast screen changer with double-sieveis controlled by hydraulic unit, which operation is easy and improve the production efficiency.

- The extruder frame adoptssquare steel, which ensures the machine works more stable at high speed.

- The motor and gearbox adoptsdirect connection, which ensurehigh output.

- Work stable ,easy operation , high performing and cost-effective.

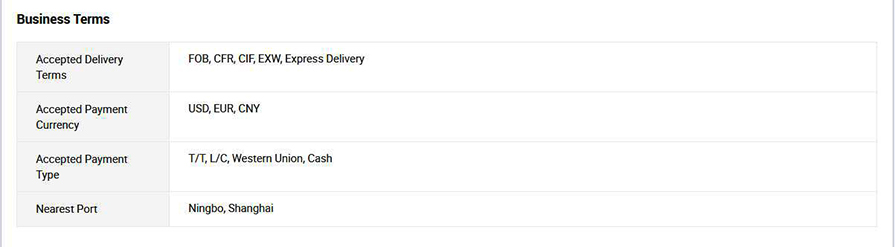

General information

|

Raw Material |

PP GPPS HIPS PE Calcium Carbonate+PP |

|

Production Capacity |

250~280kg/h (Depends on sheet thickness) |

|

Sheet Width |

≤720mm (PP); ≤680mm (PS) (Depends on sheet thickness) |

|

Sheet Thickness |

0.15~2.5 mm (Depends on material) |

|

Layer |

1 |

|

Water Consumption |

2.5~5.0m3/hr (recycled) |

|

Screw Diameter |

120mm |

|

Screw L/D Rate |

34:1 |

|

Main Motor |

90KW |

|

Electrical Consumption |

80kw/hr |

|

T-die |

850mm with Air Fan |

|

Roller Size |

Diameter 420 * 900mm |

|

Total Power |

165kw |

|

Weight |

8.0T |

|

Machine Dimension |

13.2m*1.3m*2.2m (L*W*H) |

|

Power Supply |

380V 50HZ ; 3phase 4 wire |

The machinecan be customizedaccording to customer demands.