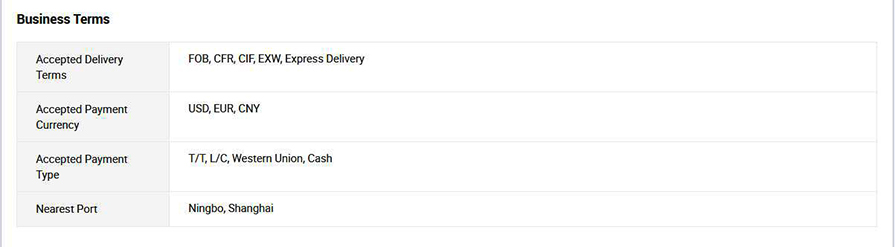

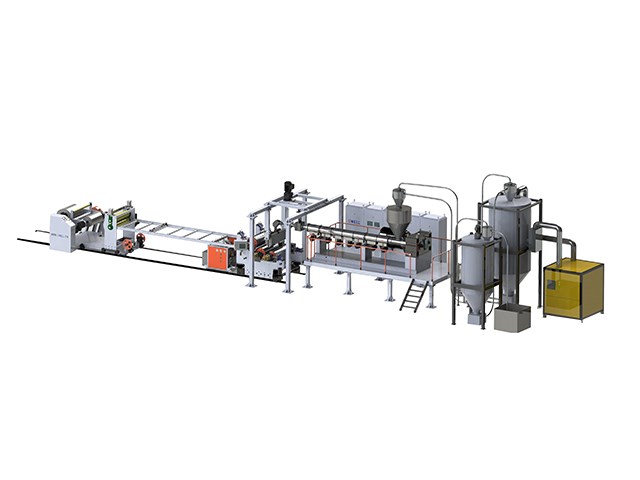

I.General

|

running condition |

380V/3P/50Hz |

|

using material |

PET |

|

Finished sheets specification |

L=800mm (can be adjusted by cutter δ=0.2-1.2mm |

|

Output capacity |

280-300kg/hr @0.6mm |

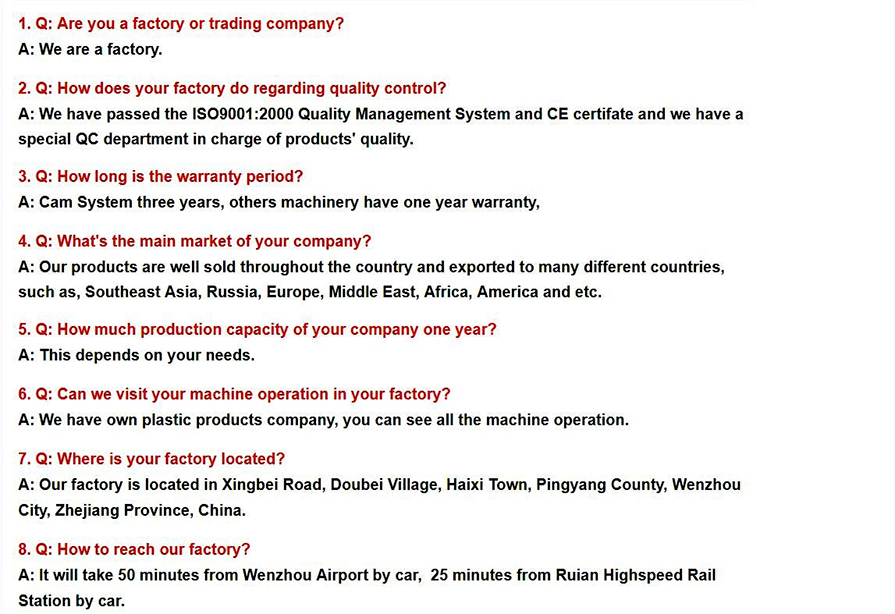

II.Detailed technical specification

1.SP120/34 single screw extruder

screw and barrel

|

Material |

38CrMoAlA |

|

Nitrided layer thickness |

0.5-0.7mm |

|

screw hardness |

HV>=740 |

|

barrel hardness |

HV>=940 |

|

L/D |

34:1 |

|

Screw diameter |

120mm |

|

Heating zones for barrel |

6 zones |

|

Total heating power |

About 50KW |

|

Heating method |

AL coating heater |

|

Cooling method |

Air cooling |

Drive

|

Motor |

AC motor |

|

brand |

SIEMENS |

|

Inverter |

ABB |

|

Drive Power |

132KW |

2.Gear pump

|

specification |

150CC |

3.hydraulic screen changer

4.T-die

|

structure of T-die |

Clothes hanger type flow channel |

|

width of die |

L=900mm |

|

plate width |

L=800mm |

|

plate thickness |

0.15-1.2mm |

5.Three-roller calendar

|

1 |

Φ350mm×950mm |

|

2 & 3 Roller diameter |

Φ500mm×2×950mm |

|

Roller Length |

L=950mm |

|

Surface roughness |

≤Ra0.025um |

|

Surface hardness |

≥HRC50 |

|

Chromium coated layer thickness |

≥0.08mm |

6.roller temperature controller

7.Cooling bracket,Side trimming unit

Cooling bracket

Side trimming unit

8.Haul off unit

|

Rubber roller material |

Nitrile rubber |

|

Specification |

Ф200mm×1100mm |

|

Max. winding diameter |

400mm |

10.Dehumidifying Dryer and crystallization system

11.electrical control system|

screen |

Siemens MP-277 |

|

PLC |

Siemens S7-200 |

|

inverter for extruder |

ABB |

|

contactor |

Siemens |

|

breaker |

IDEC |

|

breaker |

Schneider |

|

air switch |

Chint |

|

Buttons/ indication lights |

Autonics |